- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Application cases, advantages, and design selection of thin film capacitors in photovoltaic inverters

Application cases, advantages, and design selection of thin film capacitors in photovoltaic inverters

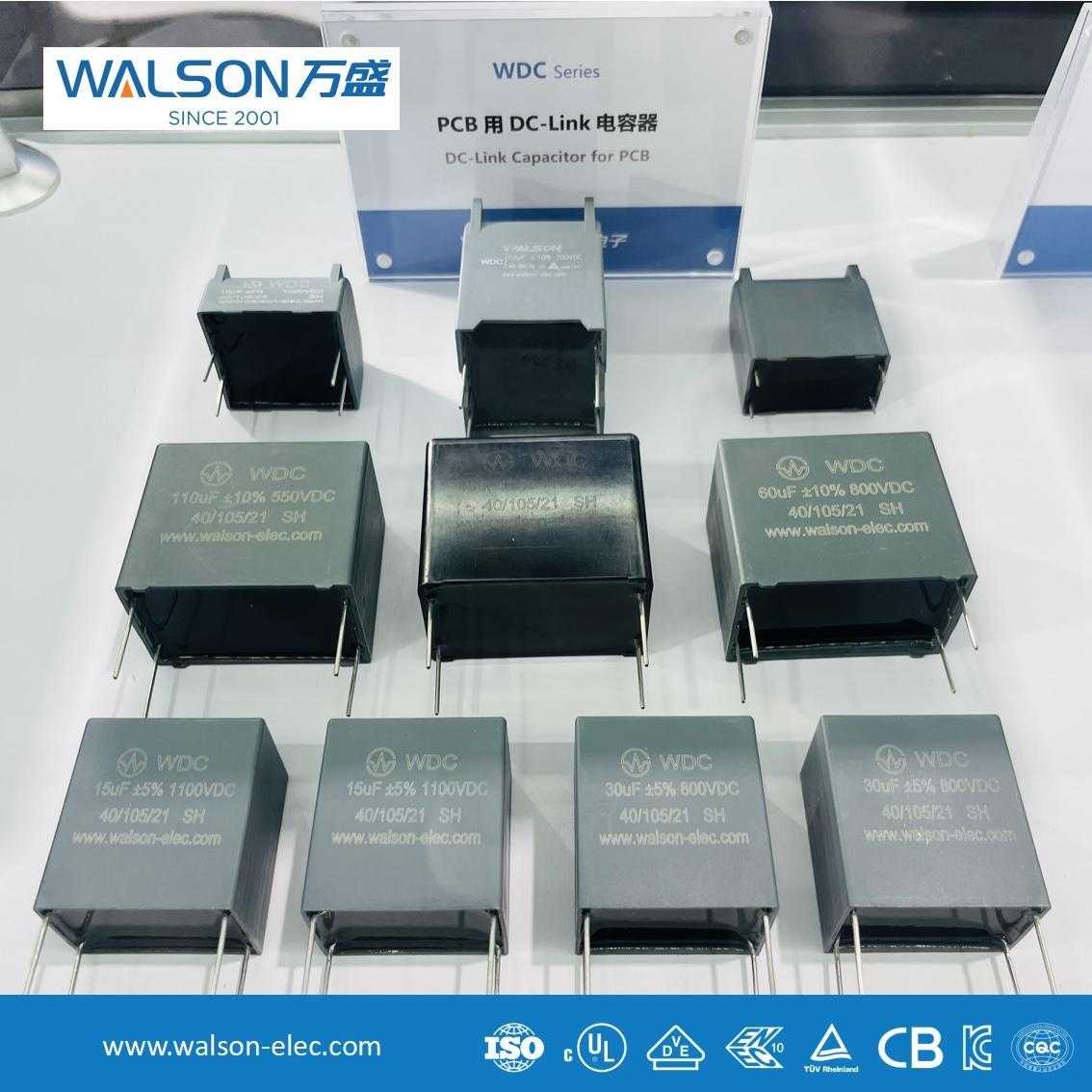

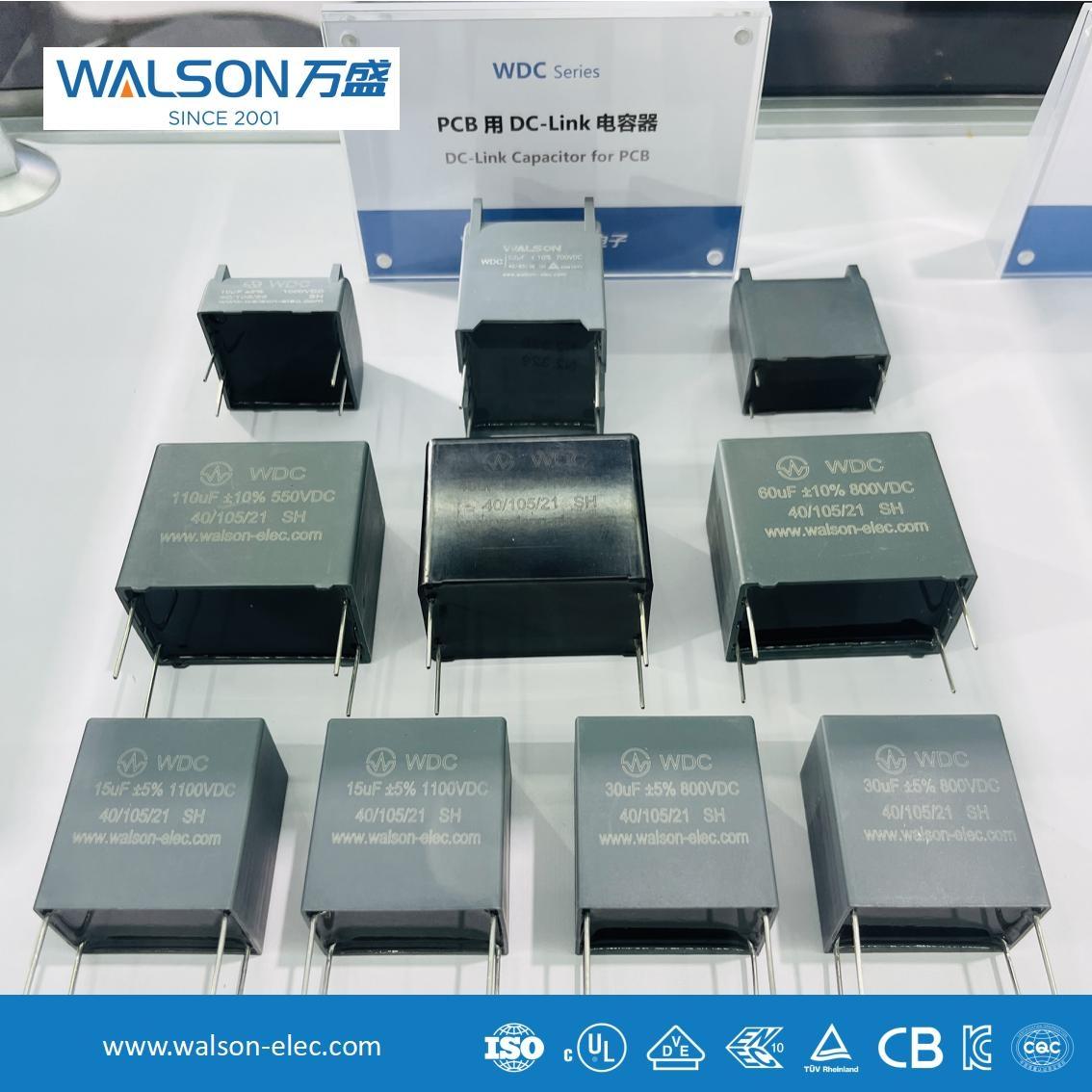

Film capacitors are critical in photovoltaic inverters, especially for handling high ripple currents. Taking a 100kW inverter as an example, the DC-LINK capacitor must withstand a maximum ripple current of 220A (under low-voltage, full-power conditions). To ensure reliability, the design requires a margin, with the actual ripple current capability exceeding 300A.

The capacitance value has minimal impact on bus voltage. For instance, at a 5kHz switching frequency, voltage fluctuations (ΔV) are negligible even with varying capacitance. Thus, the focus is not on capacitance but on the capacitor's ripple current capability. The ESR (Equivalent Series Resistance) of film capacitors is a key parameter—lower ESR allows higher ripple current and reduces the number of parallel capacitors needed. For example, a 420μF/1100V capacitor with an ESR of 1.2mΩ has a single-unit rating of 60A (at 70°C), and five parallel units can meet the 300A requirement.

Temperature control is equally important. The core temperature must stay below 85°C (with a case temperature of 70°C) to ensure longevity and performance. By optimizing ESR and thermal design, the number of parallel units can be minimized, reducing cost and size. In summary, the core criteria for DC-LINK capacitors in PV inverters are high ripple current capability and low ESR characteristics

简体中文

简体中文 English

English Español

Español