- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Difference Between Safety Capacitors and Ordinary Capacitors

Difference Between Safety Capacitors and Ordinary Capacitors

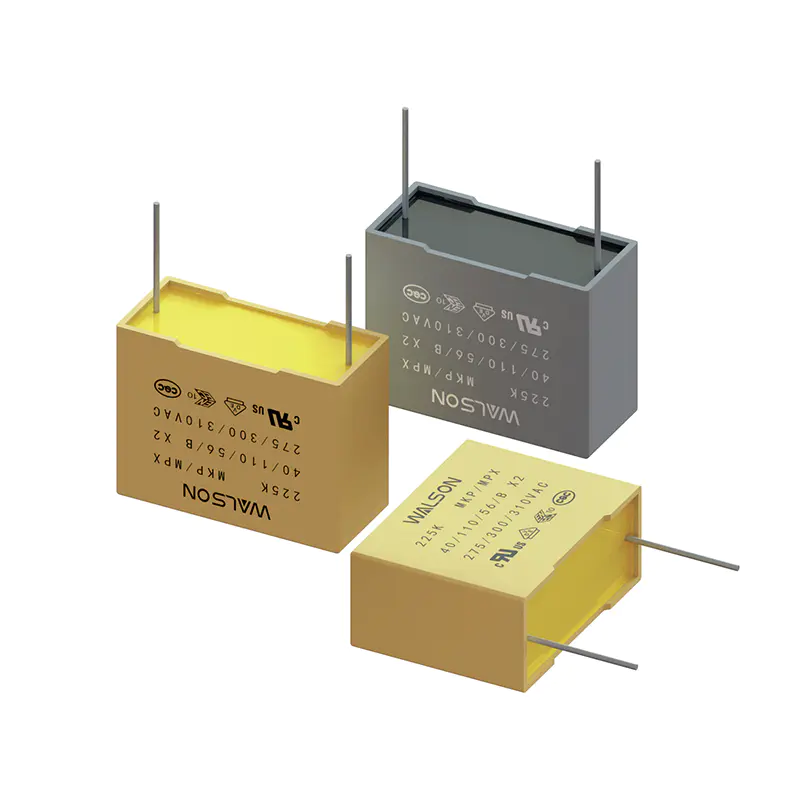

Safety capacitors are designed to prevent electric shock and ensure personal safety even after failure. They are primarily used in power supply filtering to suppress common-mode and differential-mode interference. Based on their placement, safety capacitors are categorized into X-type and Y-type: X capacitors are connected between line (L) and neutral (N), while Y capacitors are linked between line (L) and ground (G) or neutral (N) and ground (G).

Unlike ordinary capacitors, safety capacitors feature high withstand voltage and specific failure mechanisms. X capacitors have larger capacitance but require parallel safety resistors to discharge quickly when unplugged. Their DC withstand voltage often exceeds 2000V, and they must be certified, not replaceable with ordinary capacitors. Y capacitors are limited to 4700pF or less, emphasizing high withstand voltage (over 5000V DC) and low leakage current to prevent electric hazards.

Key differences include: safety capacitors discharge rapidly after power-off, avoiding residual charge that could cause electric shock; they typically fail open, whereas ordinary capacitors may fail short, posing safety risks. Additionally, safety capacitors undergo strict certifications and use flame-retardant casings for reliability under conditions.

简体中文

简体中文 English

English Español

Español