- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

What Are Plastic Film Capacitors and How Do They Enhance Electrical Performance?

What Are Plastic Film Capacitors and How Do They Enhance Electrical Performance?

In the ever-evolving world of electronics and electrical engineering, capacitors play a pivotal role in enhancing the performance and efficiency of various electrical systems. Among the many types of capacitors, plastic film capacitors have gained considerable attention for their versatility, reliability, and exceptional performance characteristics.

What Is a Plastic Film Capacitor?

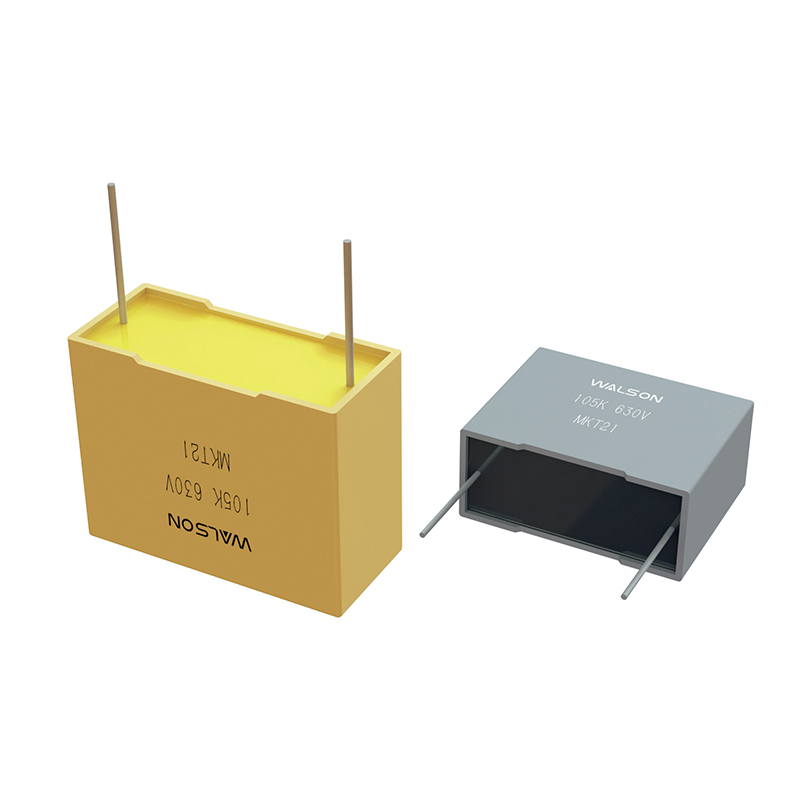

A plastic film capacitor is a type of capacitor that uses a thin layer of plastic film as the dielectric material between its conductive plates. These capacitors are widely used in a variety of electrical applications due to their electrical performance, stability, and ease of manufacturing. The film is typically made from materials such as polyester, polypropylene, or polystyrene.

Plastic film capacitors come in various configurations, including single-layer and multi-layer designs, and are often used in applications where stability over time and temperature is crucial. The dielectric material in plastic film capacitors helps to separate the plates, creating an electrical field that stores electrical energy.

How Do Plastic Film Capacitors Work?

Like all capacitors, plastic film capacitors store electrical energy temporarily. When a voltage is applied across the terminals of the capacitor, the dielectric material prevents the direct flow of current while allowing the electric field to form between the conductive plates. This process enables the capacitor to store energy, which can be discharged when needed.

The specific properties of the plastic film material, such as its dielectric constant and insulation resistance, influence how efficiently the capacitor stores and releases energy. These properties are essential for maintaining stable electrical performance in circuits.

Types of Plastic Film Capacitors

Plastic film capacitors are available in different types, each suited to specific applications. Some of the commonly used types include:

-

Polyester Film Capacitors: These are widely used due to their cost-effectiveness and reliable performance in low to moderate frequency applications.

-

Polypropylene Film Capacitors: Known for their electrical characteristics, polypropylene film capacitors are ideal for high-frequency applications and are used in circuits requiring minimal signal loss.

-

Polystyrene Film Capacitors: These capacitors are used in specialized applications where extremely low losses and high accuracy are required.

Each of these types offers distinct advantages based on the specific requirements of the electrical system or device.

Benefits of Plastic Film Capacitors

Plastic film capacitors offer numerous benefits that contribute to their widespread use across various electrical applications:

High Reliability: Plastic film capacitors are known for their robust design and high reliability. They can withstand harsh environmental conditions, including temperature fluctuations, humidity, and mechanical stress.

Excellent Temperature Stability: These capacitors can operate over a wide temperature range, making them ideal for use in environments with fluctuating temperatures.

Low Leakage Current: One of the key advantages of plastic film capacitors is their low leakage current. This characteristic ensures that the capacitor retains its stored energy for extended periods, reducing energy loss and improving efficiency.

High Voltage Capability: Depending on the material and design, plastic film capacitors can handle relatively high voltages without compromising performance, making them suitable for high-voltage applications.

Energy Efficiency: Due to their low dissipation factors, plastic film capacitors offer energy efficiency, making them suitable for power electronics and energy storage systems.

Long Lifespan: These capacitors typically have a long operational life, further enhancing their cost-effectiveness over time.

Applications of Plastic Film Capacitors

Plastic film capacitors are used in a broad range of applications across various industries, including:

-

Power Electronics: In power electronics, plastic film capacitors help manage voltage fluctuations and smooth out power delivery. They are essential in inverters, converters, and motor drives.

-

Audio and RF Circuits: In audio and radio frequency (RF) circuits, plastic film capacitors are used to filter and stabilize signals, reducing noise and distortion.

-

Energy Storage: Due to their energy efficiency and high voltage tolerance, plastic film capacitors are also used in energy storage systems such as solar power inverters and uninterruptible power supplies (UPS).

-

Automotive: These capacitors play a crucial role in automotive electronics, ensuring smooth operation of electronic systems like lighting, infotainment, and engine control units.

-

Home Appliances: In various home appliances such as washing machines, refrigerators, and air conditioners, plastic film capacitors are used to improve energy efficiency and ensure stable operation.

Plastic Film Capacitors vs. Other Types of Capacitors

When comparing plastic film capacitors to other types, such as ceramic capacitors or electrolytic capacitors, several distinct differences emerge:

| Property | Plastic Film Capacitors | Ceramic Capacitors | Electrolytic Capacitors |

|---|---|---|---|

| Dielectric Material | Plastic film | Ceramic | Electrolyte |

| Temperature Stability | Excellent | Moderate | Poor |

| Leakage Current | Low | Low to moderate | High |

| Energy Efficiency | High | Moderate | Low |

| Lifespan | Long | Moderate | Short |

As shown, plastic film capacitors stand out due to their low leakage current, energy efficiency, and long lifespan, making them more suitable for high-performance applications.

Factors to Consider When Choosing a Plastic Film Capacitor

When selecting a plastic film capacitor for a particular application, several factors should be considered:

Capacitance Value: The required capacitance value will determine the size and configuration of the capacitor. Choosing the correct capacitance ensures the capacitor performs as needed in the circuit.

Voltage Rating: It is essential to select a capacitor with an appropriate voltage rating to handle the electrical potential in the application.

Tolerance: The tolerance of the capacitor defines how much variation is acceptable from the nominal capacitance value. For precise applications, low-tolerance capacitors are preferred.

Temperature Range: Depending on the operating environment, a capacitor with a suitable temperature range is required to ensure long-term reliability.

Form Factor and Package Type: Different applications may require specific capacitor shapes, sizes, and packaging types for integration into the device or system.

Conclusion

Plastic film capacitors are integral components in modern electronics due to their performance characteristics, reliability, and versatility. From energy storage to power electronics and automotive applications, these capacitors enhance electrical performance by providing stable energy storage and efficient operation across various devices and systems. Their longevity, temperature stability, and low leakage make them a preferred choice in both consumer and industrial applications.

FAQ

1. What is the main advantage of plastic film capacitors over other capacitor types?

Plastic film capacitors offer temperature stability, low leakage current, and long operational lifespan compared to other capacitor types like ceramic or electrolytic capacitors.

2. Can plastic film capacitors be used in high-voltage applications?

Yes, plastic film capacitors can handle relatively high voltages, making them suitable for a wide range of high-voltage applications, such as power electronics and energy storage systems.

3. How long do plastic film capacitors last?

Plastic film capacitors typically have a long lifespan, often exceeding 10 to 20 years depending on the application and environmental conditions.

4. Are plastic film capacitors suitable for audio applications?

Yes, plastic film capacitors are often used in audio circuits to filter signals and reduce distortion, providing high-quality sound reproduction.

5. What factors should be considered when selecting a plastic film capacitor for an application?

Key factors to consider include capacitance value, voltage rating, tolerance, temperature range, and form factor or package type, depending on the specific needs of the application.

简体中文

简体中文 English

English Español

Español