- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why Self-Healing Film Capacitors Are Redefining Reliability in Power Electronics

Why Self-Healing Film Capacitors Are Redefining Reliability in Power Electronics

In the rapidly evolving landscape of power electronics, passive components continue to determine the operational stability of entire systems. Among them, the film capacitor has established itself as a benchmark component due to its distinctive technical strengths. One of its transformative attributes is self-healing capability, a feature that directly redefines product longevity, operational safety, and cost-effectiveness.

Understanding Self-Healing in Film Capacitors

The concept of self-healing in a film capacitor is grounded in its metallized film construction. When a localized dielectric breakdown occurs, the metallization layer around the fault area vaporizes due to the sudden energy discharge. This process isolates the defect without compromising the overall dielectric system, allowing the capacitor to continue operating normally.

This inherent mechanism provides two strategic benefits: extended service life and consistent performance in demanding circuits. Unlike capacitors that fail catastrophically after insulation breakdown, the self-healing characteristic enables gradual degradation management, thereby ensuring reliability across high-voltage and high-frequency environments.

Material Significance: Metallized Polyester Film

Different film materials contribute to the unique profile of capacitor performance. Metallized polyester film is one of the widely utilized dielectrics in self-healing capacitors. Polyester offers higher dielectric strength and compact form factors, while the thin metallization ensures rapid energy dissipation during defect isolation.

Although polypropylene is often selected for ultra-low loss applications, metallized polyester remains highly relevant for consumer electronics, automotive circuits, and lighting systems due to its cost-to-performance balance and resilience under fluctuating environmental conditions.

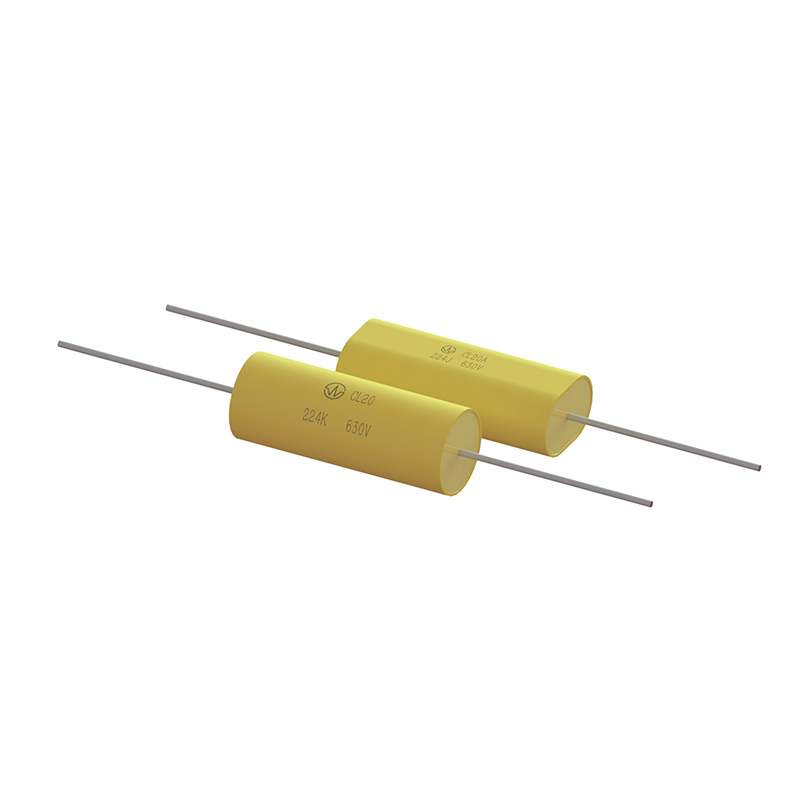

Design Influence: Axial-Type Film Capacitors

Design architecture plays a crucial role in enhancing the self-healing efficiency of film capacitors. The axial-type film capacitor is engineered with end connections aligned along the axis of the cylindrical body. This layout provides lower inductance, higher mechanical stability, and improved thermal management compared with radial or box-type equivalents.

When combined with metallized polyester, axial-type construction ensures effective self-healing under dynamic load variations, making it suitable for inverters, motor drives, and high-frequency switching applications.

Product Classification Table

| Product Type | Dielectric Material | Key Feature | Application Focus |

|---|---|---|---|

| Axial-Type Film Capacitor | Metallized Polyester | Compact, low inductance, self-healing | Motor drives, lighting, power supplies |

| Radial Film Capacitor | Metallized Polypropylene | High stability, low ESR | Renewable energy, industrial electronics |

| Box-Type Film Capacitor | Polyester / Polypropylene | Encapsulation for harsh conditions | Automotive, medical electronics |

| High Voltage Film Capacitor | Polypropylene | Long life, high dielectric strength | Power electronics, HVDC systems |

| Metallized Polyester Capacitor | Polyester Film | Self-healing, cost-efficient | Consumer and commercial electronics |

Application Relevance Across Industries

The impact of self-healing is visible across diverse application domains. In power electronics, film capacitors ensure reliable DC-link stabilization under pulsed loads. In lighting systems, metallized polyester capacitors sustain flicker-free operation with reduced maintenance cycles. Within automotive electronics, axial-type capacitors contribute to circuit protection and smooth operation of control units under thermal stress. Additionally, renewable energy inverters demand high-reliability capacitors where self-healing minimizes downtime risks.

Reliability and Performance Metrics

Self-healing not only extends operational life but also directly improves performance metrics such as:

- Reduced Equivalent Series Resistance (ESR): ensuring higher efficiency in high-frequency circuits.

- Consistent Capacitance Retention: providing stability under voltage stress.

- Thermal Endurance: safeguarding performance in elevated temperature environments.

These attributes make film capacitors irreplaceable in advanced designs that prioritize operational reliability over short-term cost reduction.

Market Perspective

As global demand for electrification, renewable integration, and automotive electronics continues to expand, the market share of film capacitors with self-healing technology is expected to grow significantly. Industry trends emphasize long-life components capable of reducing system failures and total cost of ownership. Manufacturers are therefore investing in refined metallization techniques, enhanced axial designs, and hybrid dielectric combinations to maximize self-healing efficiency while meeting evolving regulatory and performance standards.

简体中文

简体中文 English

English Español

Español