- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

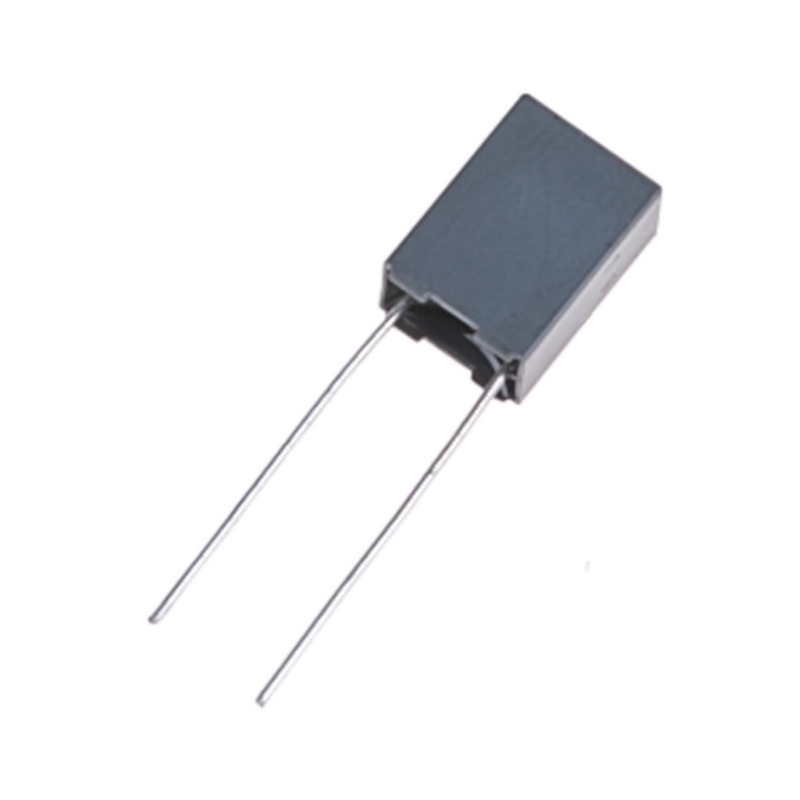

How does the Box-Type Metallized Polyester Film Capacitor achieve a larger capacitance in a smaller volume?

How does the Box-Type Metallized Polyester Film Capacitor achieve a larger capacitance in a smaller volume?

The capacitance of a capacitor is closely related to factors such as electrode materials, dielectrics, and structural design. The Box-Type Metallized Polyester Film Capacitor has carefully considered the selection of electrode and dielectric materials, laying the foundation for achieving a small volume and large capacity.

The use of metallized film electrodes is an important factor in achieving this characteristic of the box-type metallized polyester film capacitor. Traditional electrode materials, such as metal foil, have problems such as large thickness and occupying a lot of space. The metallized film electrode is formed by depositing an extremely thin metal film on the surface of the polyester film through processes such as vacuum evaporation. The thickness of this metal film can be precisely controlled at the micron or even nanometer level, which greatly reduces the space occupied by the electrode itself compared to traditional metal foil electrodes. More importantly, this extremely thin metallized film makes it possible to miniaturize the capacitor without affecting the electrical performance of the capacitor. When the capacitor is working, the metallized film electrode also has unique advantages. Once an abnormal situation such as local breakdown occurs, the metallized electrode can react quickly, and the metal film around the breakdown point can be detached by melting or evaporating itself, thereby restoring the insulation state and ensuring that the capacitor continues to work normally. This self-healing property not only improves the reliability of the capacitor, but also makes it unnecessary to reserve too much space to deal with possible failures when designing the capacitor, which further helps to achieve the goal of small volume and large capacity.

High-performance polyester film dielectrics also contribute to this. As a dielectric of capacitors, polyester film has many excellent properties. First, polyester film has high insulation performance, which can effectively prevent current leakage and ensure the stability of capacitors when storing and releasing charges. Stable insulation performance is the basis for ensuring the normal operation of capacitors, allowing capacitors to operate reliably in a smaller volume. Secondly, polyester film has a higher dielectric constant. The dielectric constant is an important indicator for measuring the ability of dielectrics to store charge. A higher dielectric constant means that under the same electrode area and electrode spacing, the capacitor can store more charge, thereby achieving a larger capacitance. Polyester film has stable chemical properties and high mechanical strength, and can withstand a certain degree of stretching and bending without affecting its electrical properties. This good mechanical property enables polyester film to be processed into various shapes and sizes during the production of capacitors to meet different volume requirements while ensuring the stability of capacitance. The good temperature resistance of polyester film enables it to maintain stable performance in a wide temperature range, which also provides a guarantee for the capacitor to achieve small volume and large capacity in different environments.

In addition to the selection of materials, the production process of box-type metallized polyester film capacitors also plays a key role in achieving small volume and large capacity. In the film preparation process, through multiple precisely controlled steps such as polymerization reaction, extrusion molding, stretching and orientation, polyester film with uniform thickness and stable performance can be produced. Precisely controlled process parameters ensure the quality of polyester film, so that it still has good electrical and mechanical properties at a small thickness, which provides the possibility of reducing the volume of capacitors. During the metallization process, electron beam evaporation or magnetron sputtering and other technologies are used in a high vacuum environment to heat and evaporate the metal material and deposit it on the surface of the polyester film to form a uniform metallization layer. Precisely controlling the thickness and uniformity of the metallization layer not only ensures the electrical performance of the capacitor, but also helps to reduce the overall volume. In the winding process, the metallized polyester film is wound in a specific way to form a capacitor core. Special winding methods, such as stacking two layers of metallized film in reverse before winding to achieve a non-inductive winding structure, can ensure the performance of the capacitor while reducing the volume of the core as much as possible. The gold spraying process and assembly packaging process have also been carefully designed and strictly controlled to ensure good electrical connection and protect the internal core of the capacitor without adding too much extra volume.

From the perspective of practical application, the small size and large capacity of the box-type metallized polyester film capacitor make it widely used in many fields. In electronic circuits, it can be used for functions such as DC isolation, coupling, bypass and filtering. In the limited circuit board space, with its advantages of small size and large capacity, it can efficiently complete these functions and ensure the normal operation of the circuit. In the field of lighting, especially in the electronic ballast of gas discharge lamps, it can be used for important tasks such as power factor correction. The smaller size enables it to be easily installed inside the ballast, while the larger capacitance meets the performance requirements of the ballast for capacitors, improves the power factor of the lighting system, and reduces the loss of reactive power. In power electronic devices such as switching power supplies and inverters, as well as various sensors, actuators and controller circuits in the field of industrial control, box-type metallized polyester film capacitors also play an important role. Its small size and large capacity characteristics meet the requirements of these devices for miniaturization and high performance of components, providing a guarantee for the stable operation of the equipment.

简体中文

简体中文 English

English Español

Español