- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why can Capacitor Module for Electromagnetic Interference Suppression maintain stable electrical performance?

Why can Capacitor Module for Electromagnetic Interference Suppression maintain stable electrical performance?

I. High-quality dielectric materials lay a stable foundation

(I) Ceramic dielectric: a perfect combination of high stability and high-frequency adaptability

Ceramic materials occupy an extremely important position in Capacitor Module for Electromagnetic Interference Suppression. Taking multilayer ceramic capacitors as an example, the ceramic dielectrics such as barium titanate commonly used in them have many significant advantages. High dielectric constant is one of the outstanding characteristics of this type of ceramic dielectric, which enables capacitors to achieve large capacitance in a relatively small volume, which is highly consistent with the development trend of miniaturization and integration of modern electronic devices. In some portable electronic devices with extremely stringent space requirements, such as smart phones and tablets, this small volume and large capacity feature is particularly important, which makes it possible to efficiently utilize the limited space inside the device.

More importantly, ceramic dielectrics have excellent temperature stability. Under different operating temperature environments, their capacitance changes very little. Whether in a cold low-temperature environment or in a hot high-temperature environment, ceramic dielectrics can ensure that the capacitance of the capacitor remains within a relatively stable range. In extremely low temperature environments, such as the temperature of tens of degrees below zero that some outdoor electronic equipment may face, the capacitance change of ceramic dielectric capacitors can still be controlled within a very small range, and the capacitance will not drop significantly due to low temperature, thus ensuring the normal operation of the equipment in low temperature environments. Similarly, in high temperature environments, such as the high temperature environment that may be generated by industrial equipment during long-term operation, ceramic dielectric capacitors can also work stably, and the stability of capacitance provides a solid guarantee for the continuous and reliable operation of the equipment.

In addition, ceramic dielectrics also perform very well in high-frequency circuits. With the continuous development of electronic technology, the operating frequency of electronic equipment is getting higher and higher, and the performance requirements for capacitors in high-frequency environments are becoming increasingly stringent. In high-frequency circuits, such as the common-mode noise suppression scenario of switching power supplies, when the frequency is as high as MHz or even higher, some traditional capacitors often have unsatisfactory suppression effects due to problems such as parasitic inductance. However, products such as surface mount Y capacitors using advanced ceramic dielectrics show obvious advantages. Its parasitic inductance can be reduced to an extremely low level, and its high-frequency suppression capability is greatly improved. In practical applications, it can effectively reduce the interference of common mode noise spectrum extending to hundreds of MHz and above, ensure the normal operation of the circuit in a high-frequency environment, and provide a stable electromagnetic environment for the transmission and processing of high-speed signals.

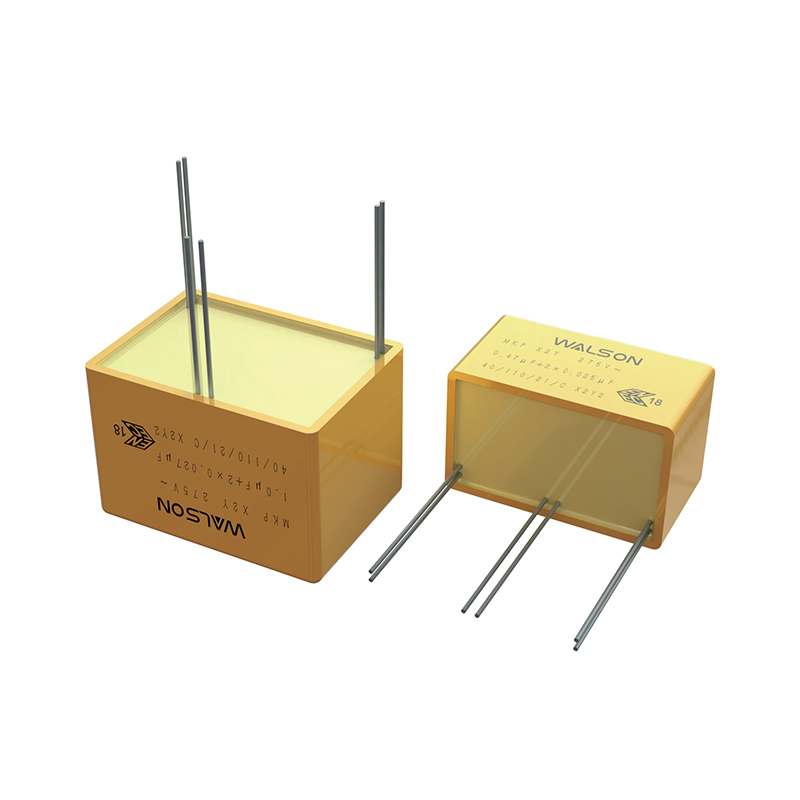

(II) Polypropylene film: an ideal choice for pulse voltage

For some special applications that require high pulse voltage tolerance, polypropylene film has become an ideal dielectric choice. Polypropylene film has been widely used in products such as X2 capacitors that suppress power supply electromagnetic interference. Polypropylene film has a series of excellent properties that enable it to work stably under high pulse voltage environments.

High insulation resistance is one of the important characteristics of polypropylene film. This means that during the operation of the capacitor, the leakage current through the dielectric is extremely small, which can effectively reduce energy loss and improve the working efficiency of the capacitor. When facing high voltage, polypropylene film can withstand a large electric field strength without being broken down, and has strong dielectric strength. At the same time, its loss tangent is small, which further reduces the energy loss of the capacitor during operation, effectively controls the heating phenomenon, and is conducive to the capacitor maintaining stable performance under long-term high-load working conditions.

In practical applications, such as in some power electronic equipment, the power supply may be impacted by various transient pulse voltages, the amplitude of which may be as high as several thousand volts. In this case, capacitors using polypropylene film as the dielectric can work stably without breakdown. It can effectively reduce the unnecessary transient pulse voltage in the power supply to a level that the electronic equipment can withstand, meeting the strict requirements of electronic equipment for power supply stability. Even under harsh working conditions where high-amplitude pulse voltage impacts are frequently encountered, polypropylene film dielectric capacitors can still maintain good performance and provide reliable power supply filtering and interference suppression functions for the stable operation of the equipment.

II. Advanced manufacturing process carves stable quality

(I) Winding process: precise control achieves stable performance

Film capacitor winding

In the process of making film capacitors with polypropylene film as the dielectric, the winding process is one of the key links that affect the performance of the capacitor. Tension control during the winding process is crucial. Through precise calculation and adjustment, the winding tension can be reasonably set according to the width, thickness and other parameters of the film, so that the winding tightness can be kept consistent. When making high-performance capacitors that suppress power supply electromagnetic interference, the winding tension is determined strictly according to a specific formula. Such precise tension control can effectively reduce the gap between the membranes and the wrinkles of the membrane, thereby increasing the free starting voltage of the capacitor. If the winding tension is too large, the film may be overstretched or even cracked, affecting the insulation performance and service life of the capacitor; if the winding tension is too small, the winding will not be tight enough, the gap between the membranes will increase, and it is easy to cause problems such as partial discharge, which will also reduce the performance of the capacitor.

At the same time, the misalignment distance between the two films during winding also needs to be strictly controlled. Too large or too small misalignment will cause poor contact between the film layer and the gold spray, thereby affecting the overall performance of the capacitor. In the gold spraying process, good contact between the film layer and the gold spraying can ensure the effective conduction of current and reduce contact resistance. If the contact is poor, during the operation of the capacitor, especially in the case of high current pulse testing or discharge, the product will heat up due to large losses, and may even cause failure. In addition, the rollers on the winding machine that are in contact with the metal layer must be kept clean and run smoothly. Because impurities on the roller surface or unsmooth operation may cause longitudinal strain on the metal layer, once the metal layer is strained, the loss of the capacitor will increase and the electrical performance will be seriously affected. By precisely controlling these key parameters and links in the winding process, it is possible to ensure that the film capacitor maintains a good internal structure during the manufacturing process, laying a solid foundation for its stable electrical performance.

Multilayer Ceramic Capacitor Stacking

Multilayer ceramic capacitors are made using a unique stacking process. This process requires multiple ceramic dielectric layers and electrode layers to be stacked alternately, and then sintered at high temperature to form a whole. During the stacking process, extremely high requirements are placed on the thickness and alignment accuracy of each layer. The precise control of the thickness of each layer is directly related to the capacitance accuracy and stability of the capacitor. If the thickness of a certain layer of ceramic dielectric deviates, the capacitance of the entire capacitor may deviate from the design value, affecting its filtering, coupling and other functions in the circuit. Similarly, the uneven thickness of the electrode layer will also affect the resistance characteristics and current conduction performance of the capacitor.

The alignment accuracy between the electrode layer and the ceramic dielectric layer has an important influence on the internal electric field distribution of the capacitor. If the electrode layer and the ceramic dielectric layer are not aligned accurately, the electric field distribution will be uneven, and the electric field strength may be too high in some local areas, which can easily cause problems such as local breakdown of the capacitor, seriously affecting its reliability and service life. Through advanced manufacturing equipment and precise process control, the thickness and alignment accuracy of each layer can be precisely controlled. Some high-end multilayer ceramic capacitor manufacturing processes can achieve extremely thin dielectric layers and fine electrode patterns, which not only further improves the performance of the capacitor, such as improving its withstand voltage performance and reducing equivalent series resistance, but also meets the needs of continuous miniaturization of electronic equipment, enabling capacitors to achieve more stable and efficient electrical performance in a smaller volume.

(II) Gold spraying and packaging process: all-round protection to ensure stable operation

Gold spraying process

Gold spraying process is a key link in the production of electromagnetic interference suppression capacitors. Taking Y2 type film capacitors as an example, the contact state between the core end face and the gold spraying layer is directly related to the performance and reliability of the capacitor. If the two are in poor contact, after a large current pulse test or a charge and discharge process, the product will heat up due to large losses, and may even fail. In order to ensure good contact, it is necessary to select suitable materials and accurately control process parameters during the gold spraying process.

In terms of material selection, for example, when using a zinc-aluminum evaporation film with thickened edges, in order to reduce the contact resistance, pure zinc material can be used as a primer first, and then zinc-tin alloy wire can be sprayed. Such a material combination can make zinc and zinc contact better, thereby improving the conductivity between the gold spraying layer and the evaporation electrode. In terms of process parameter control, the distance between the gold spraying gun nozzle and the end face of the core is usually controlled within a specific range, generally about 190mm. Too large a distance may cause uneven gold spraying and affect the quality of the gold spraying layer; too small a distance may cause damage to the core. Because the presence of impurities may affect the adhesion and conductivity of the gold spraying material. The appropriate thickness can not only ensure that the gold spraying layer has good conductivity, but also avoid cost increases or other performance problems caused by excessive thickness. Through the careful selection and control of the gold spraying material and process parameters, it can ensure that the gold spraying layer has good contact with the evaporation electrode, reduce the contact resistance of the capacitor, and improve its stability and reliability under working conditions such as high current.

Packaging process

The packaging process has a vital impact on the protection performance and service life of the electromagnetic interference suppression capacitor. Commonly used packaging materials include PBT engineering plastics with good flame retardancy, epoxy resin, etc. Different packaging materials have their own characteristics. PBT engineering plastics have good mechanical strength and flame retardancy, which can provide reliable mechanical protection for capacitors to prevent damage caused by external impact during transportation, installation and use. In some applications with high safety requirements, such as power modules of electronic equipment, the flame retardancy of PBT engineering plastics can effectively prevent fires and ensure the safety of equipment and personnel. Epoxy resin has excellent sealing and electrical insulation properties. During the packaging process, when epoxy resin is used for potting, the uniformity and sealing of the potting must be ensured. Uniform potting can fully protect the internal parts of the capacitor and avoid local weak points. Good sealing can prevent impurities such as moisture and dust from entering the capacitor. The intrusion of moisture may cause corrosion of the metal parts inside the capacitor and affect its electrical performance; the accumulation of impurities such as dust may cause problems such as local discharge and reduce the reliability of the capacitor. After potting the capacitor, vacuum treatment is sometimes required. When making high-performance capacitors to suppress power supply electromagnetic interference, the vacuum machine pressure needs to be controlled at ≤ - 0.06 MPa, the vacuum pumping times need to be ≥ 3 times, and finally baked. By first controlling the baking temperature at 80°C for a certain period of time, and then raising the temperature to 95°C for a longer period of time, it is possible to effectively remove the bubbles that may exist inside, improve the packaging quality, and further enhance the protection performance and electrical performance stability of the capacitor.

简体中文

简体中文 English

English Español

Español