- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

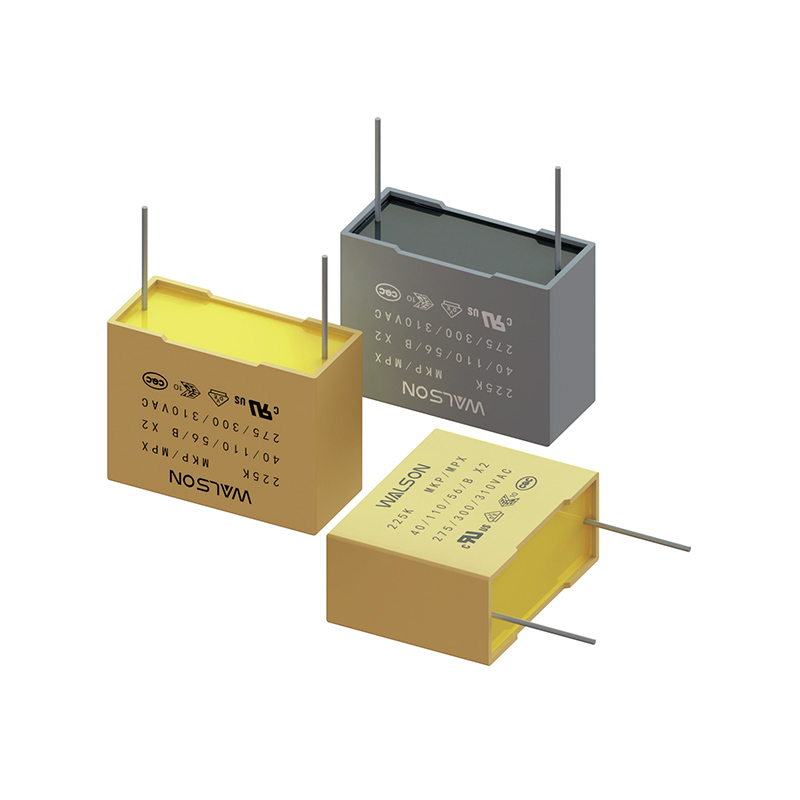

Revealing the secrets of "X2 thin-film EMI suppression capacitor": invisible noise reducer and safety valve inside electrical appliances

Revealing the secrets of "X2 thin-film EMI suppression capacitor": invisible noise reducer and safety valve inside electrical appliances

Deep inside every modern electrical appliance plugged into a power source, a silent battle is constantly being waged. The surging alternating current carries invisible "noise pollution" - electromagnetic interference (EMI). They are like static ghosts in the digital age, threatening not only the precise operation of the equipment itself, but also the peace of neighboring electrical appliances. The first line of defense standing at the power inlet, its name itself reveals its dual mission: X2 thin-film EMI suppression capacitor. This is by no means a boring part code, but an accurate summary of its core technology and key responsibilities.

1. Cornerstone: Capacitors are more than just containers for storing electricity

When it comes to capacitors, many people may only think of the basic concept of "storing charge". However, in the complex movement of electronic systems, its role is far from that simple. It is more like a precise conductor of energy flow, sensitively capturing harmful high-frequency clutter on the power line. How does it do it? By showing extremely low impedance in the face of high-frequency noise, it provides these uninvited guests with a fast discharge channel to the "ground" or "neutral line"! Think about it, if it is not efficiently filtered at the power inlet, the spike pulses and radio frequency interference generated by the switching power supply and the start and stop of the motor will not be rampant inside the power grid and equipment?

2. Core materials: the "self-healing" magic and toughness of the film

The word "film" reveals the core secret inside it. This usually refers to metallized polypropylene film-a structure in which extremely thin metal electrodes (such as zinc and aluminum) are precisely evaporated on a polypropylene film substrate. This design brings an almost magical "self-healing" property: when the local area encounters unbearable high pressure and a tiny breakdown occurs, the evaporated metal layer around the breakdown point will instantly vaporize and evaporate, just like a wound that automatically scabs and heals, isolating the fault point and allowing the capacitor to continue to work reliably as a whole. Isn't this the extraordinary vitality that the material gives to electronic components? Not only that, polypropylene film also contributes low loss, excellent frequency response, high insulation resistance and good temperature stability. More importantly, it is naturally non-polar and perfectly adapts to the alternating positive and negative impacts of AC power. This micron-sized film is the secret of the stable and efficient operation of capacitors.

3. Safety certification: X2 level, "explosion-proof shield" on the high-voltage front

Dare to directly bridge between the live wire (L) and the neutral wire (N) of the AC power supply, and face the lightning surge or high-energy pulse generated by the switching moment in the power grid - what kind of courage and guarantee does this require? "X2" is one of the highest safety certification levels granted to such application scenarios by the International Electrotechnical Commission IEC 60384-14 standard. What does it mean? It means that the capacitor is designed for the "heartland" of high-voltage AC lines and must have a strong physique to withstand extreme surge impacts. However, more critical than tolerance is its failure mode: even if it fails under the most severe conditions, it must "quietly and safely exit", either becoming an open circuit or maintaining extremely high impedance. What is the core requirement? Absolutely avoid the risk of fire or electric shock! This is an iron rule engraved in the safety gene, and it is also the cornerstone for it to be used in thousands of household appliances around the world and pass the strict safety certifications of various countries such as UL, VDE, CQC, and KC. Imagine, if there is no built-in "safety valve", how much potential hidden danger will it bring if the components are placed directly on the high-voltage AC line?

4. Core Mission: Suppress EMI and Protect the Peace of Radio Waves

Its ultimate goal is clearly imprinted in the name: electromagnetic interference (EMI) suppression. EMI is like invisible electronic smoke, which is generated by switching power supplies, variable frequency motors and other equipment, or invaded from the external power grid. What are its hazards? At the least, it will cause unstable equipment operation, screen flickering, and data errors; at the worst, it will interfere with medical equipment, communication signals, and even cause equipment damage. X2 thin-film electromagnetic interference suppression capacitors are a weapon to fight this kind of "pollution". How does it work? At the frequency of interference noise (especially high frequency band), it instantly "transforms" into a low impedance path, efficiently "draining" these harmful energies to the ground or neutral line, preventing them from spreading outward along the power line to pollute the power grid, or invading the sensitive circuits of the equipment. It often works side by side with common mode inductors to form an EMI filtering network at the power inlet. It can be said that the harmonious coexistence of electrical appliances in our homes without interfering with each other depends largely on these "electromagnetic silencers" who work silently.

V. Value and Application: Guardian of Stability and Safety

In summary, the core value of X2 thin-film electromagnetic interference suppression capacitors lies in its triple guarantee:

Safety Guard: Meets the strict X2 safety level, and the failure protection mechanism ensures inherent safety in high-voltage AC applications.

Reliable foundation: Thin-film dielectrics (especially polypropylene) and self-healing properties give it an ultra-long service life and excellent reliability.

Noise reduction expert: Excellent high-frequency characteristics and low loss make it an efficient solution for suppressing conductive EMI/RFI noise.

Because of this, you can find it in almost any device that needs to be connected to an AC power source and meets electromagnetic compatibility (EMC) regulations: from the switch power input of computers and TVs to the compressor drive circuit of refrigerators and air conditioners; from the core of LED lighting drivers to the power inlet of industrial inverters and power tools. It is not only the "stabilizing force" for the stable operation of the equipment itself, but also the "environmental protection pioneer" for maintaining the clean electromagnetic environment of the power grid.

The next time you press the switch of an electrical appliance and enjoy the convenience brought by technology, you might as well think of the small component called "X2 thin-film electromagnetic interference suppression capacitor" hidden deep in the power inlet. It does not have a cool appearance, but it has the magic of "self-healing" and wears the "X2" safety medal. It filters electromagnetic noise day and night and protects the safety and tranquility of the equipment. It is an indispensable invisible hero in the modern electronic world. Every word in its name carries a heavy technical connotation and safety commitment.

简体中文

简体中文 English

English Español

Español