- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why can Metallized Polyester Film Capacitor stand out in the electronics field with its core advantages?

Why can Metallized Polyester Film Capacitor stand out in the electronics field with its core advantages?

Unique structure, foundation of performance

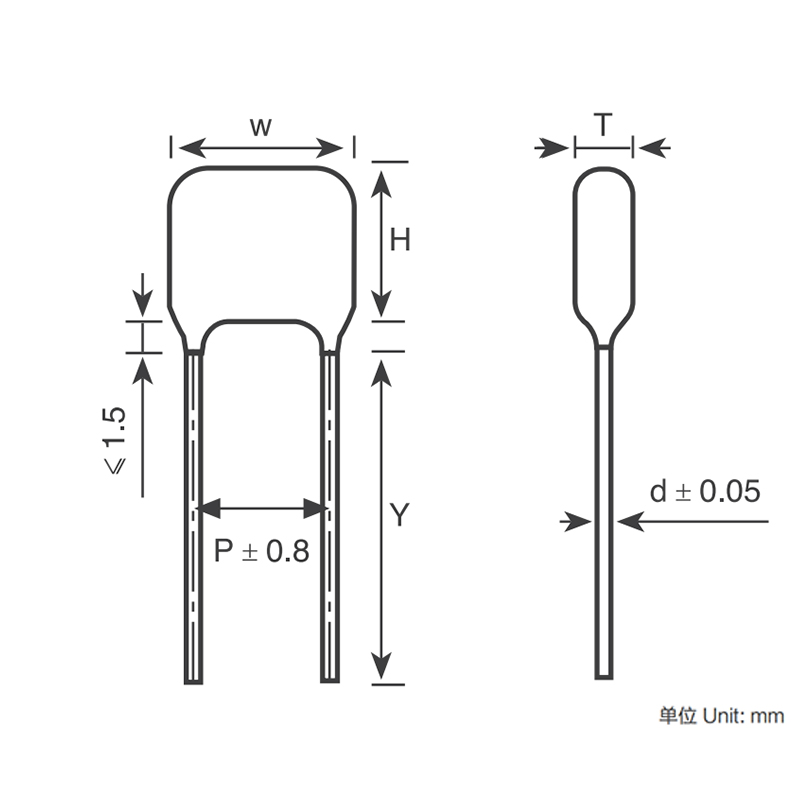

The structure of Metallized Polyester Film Capacitor is the key to its excellent performance. Metallized polyester film and non-inductive winding structure constitute its core architecture. Polyester film itself has excellent electrical insulation performance, which can effectively prevent current leakage and ensure the safety of circuit operation; at the same time, it also has good mechanical properties, and is not easy to deform and damage during production and processing and equipment operation, and has strong stability; and has good chemical stability, can adapt to a variety of complex use environments, and does not easily react chemically with other substances.

Through vacuum evaporation technology, an extremely thin metal layer is formed on the surface of the polyester film, creating a metallized polyester film. This metal layer acts as the electrode of the capacitor, enabling the capacitor to store and release electrical energy. More importantly, it gives the capacitor a unique self-healing property. When the capacitor encounters voltage fluctuations, overcurrent and other situations that lead to local breakdown, the metal layer on the surface of the metallized polyester film will evaporate quickly, remove the conductive material around the breakdown point, restore the insulation performance of the capacitor, avoid further expansion of the fault, and ensure that the capacitor can continue to work stably.

The non-inductive winding structure is also of great significance. During the winding process of traditional winding capacitors, a certain inductance will be generated between the electrodes. This inductance will have a negative impact on the performance of the capacitor in high-frequency application scenarios, leading to signal distortion, circuit instability and other problems. The non-inductive winding structure adopted by the metallized polyester film capacitor cleverly offsets the inductance of the capacitor through a special winding method, greatly reducing the equivalent series inductance. This enables the metallized polyester film capacitor to maintain stable performance in high-frequency circuits and provide reliable protection for the normal operation of high-frequency electronic equipment.

Flexible adaptation, space optimization

The metallized polyester film capacitor has a wide capacitance range, which enables it to be flexibly used in different types of electronic equipment and circuits. In some circuits with high signal processing requirements, such as audio and video signal processing circuits, precise capacitance values are required to achieve signal filtering, coupling and other functions. Metallized polyester film capacitors can accurately provide the corresponding capacitance to ensure the purity and stability of the signal, thereby improving the playback quality of audio and video equipment and allowing users to have a better audio-visual experience.

In the power management system, whether a small-capacity capacitor is needed for circuit voltage stabilization and filtering, or a large-capacity capacitor is needed for energy storage, metallized polyester film capacitors can meet the needs. For the power circuit of small electronic equipment, small-capacity metallized polyester film capacitors can effectively filter out the clutter in the power supply and ensure stable power supply for the equipment; and in some occasions where a large amount of electrical energy needs to be stored, such as the battery management system of new energy vehicles, large-capacity metallized polyester film capacitors can play an energy storage role and provide stable power support for the operation of the vehicle.

In addition to the wide capacitance range, the advantages of metallized polyester film capacitors are also very prominent in small size and light weight. As today's electronic devices are developing towards thinness and miniaturization, internal space has become extremely valuable. Take smartphones as an example. Many electronic components are integrated inside, and the size of each component needs to be strictly controlled. With advanced manufacturing processes and material properties, metallized polyester film capacitors have greatly reduced their own size and weight while ensuring performance. It can efficiently complete filtering, energy storage and other functions in the limited internal space of the mobile phone, help the mobile phone to achieve a light and thin design, and improve the portability and aesthetics of the product. Similarly, in portable electronic devices such as tablets and smart watches, metallized polyester film capacitors also play an important role, providing strong support for the miniaturization of equipment.

Reliable, durable, and safe escort

Self-healing performance is an important feature of metallized polyester film capacitors that distinguishes them from other capacitors, and is also an important guarantee for their reliability and durability. During the operation of electronic equipment, voltage instability and excessive current often occur, which can easily lead to local breakdown of capacitors and cause equipment failure. The self-healing performance of metallized polyester film capacitors can respond quickly at the moment of local breakdown, remove conductive materials through evaporation of the metal layer, restore insulation performance, and enable the capacitor to continue to work normally.

In the monitoring equipment of the power system, the equipment needs to run uninterruptedly for a long time, the working environment is complex and changeable, and the voltage and current fluctuate frequently. The self-healing performance of metallized polyester film capacitors can ensure the stable operation of monitoring equipment in such an environment, reduce equipment downtime caused by capacitor failure, reduce maintenance costs, and ensure the safe and stable operation of the power system. In the power module of the communication base station, the capacitor also needs to have high reliability. The self-healing characteristics of the metallized polyester film capacitor enable it to meet the needs of long-term and stable operation of the communication base station and ensure the continuous and stable transmission of the communication signal.

The flame-retardant epoxy resin coating provides a solid guarantee for the safety of the metallized polyester film capacitor. During the operation of electronic equipment, there is a risk of fire due to heating of components and short circuit of circuits. The flame-retardant epoxy resin coating on the surface of the metallized polyester film capacitor can effectively prevent the spread of flames in high temperature environments and reduce the possibility of fire. This coating not only has excellent flame retardant properties, but also can enhance the mechanical strength of the capacitor, making it less likely to be damaged when impacted by external forces; at the same time, it has good moisture resistance, protecting the polyester film and metal electrodes inside the capacitor from erosion by humid environments, and extending the service life of the capacitor.

In the field of automotive electronics, the interior space of the car is small and the electronic equipment is dense. Once a fire occurs, the consequences are disastrous. The flame-retardant epoxy resin coating of the metallized polyester film capacitor enables it to meet the strict safety requirements of automotive electronics and operate safely and reliably in components such as the engine control system and in-vehicle entertainment system of the car. In the field of aerospace, the safety requirements for electronic components are extremely high. With flame-retardant epoxy resin coating, metallized polyester film capacitors can adapt to the working requirements of aerospace equipment in extreme environments, and escort the safe operation of satellite communications, aviation navigation and other systems.

Multiple applications, broad prospects

The many excellent properties of metallized polyester film capacitors have made them widely used in various fields. In the field of consumer electronics, from common TVs and audio equipment to digital cameras and laptops, they are inseparable from the support of metallized polyester film capacitors. In TVs, it is used for signal filtering and coupling to ensure the clarity and stability of image and sound signals; in audio equipment, it can improve the quality of audio signals, allowing users to enjoy high-quality music.

In the field of industrial control, metallized polyester film capacitors play an important role. In the inverter, it can stabilize the voltage and current in the circuit and improve the accuracy and stability of variable frequency speed regulation; in the servo drive, it can achieve precise control of the motor to ensure the efficient operation of industrial production; in the programmable logic controller, it provides stable power supply and signal processing support for the logic control circuit, helping industrial automation production.

In the field of new energy, with the rapid development of renewable energy such as solar energy and wind energy, the application of metallized polyester film capacitors is becoming more and more widespread. In solar photovoltaic power generation systems, it is used to store and convert electrical energy to improve power generation efficiency; in wind power generation systems, it can stabilize power output and ensure that electrical energy is smoothly integrated into the power grid.

简体中文

简体中文 English

English Español

Español