- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why does the Capacitor Module for Electromagnetic Interference Suppression use a specific structure?

Why does the Capacitor Module for Electromagnetic Interference Suppression use a specific structure?

Overview of electromagnetic interference and suppression requirements

In an environment full of modern electronic devices, electromagnetic interference is like a ghost hidden in the dark, threatening the stable operation of the equipment at all times. From smartphones and computers used in daily life to precision instruments and automation equipment in industrial production, all kinds of electronic devices will generate electromagnetic signals when working. These signals are intertwined and interfered with each other, which may cause equipment performance degradation, data transmission errors, and even cause failures. For example, in the field of medical equipment, electromagnetic interference may affect the detection accuracy of electrocardiogram monitors, nuclear magnetic resonance imaging equipment, etc., endangering the diagnosis and treatment of patients; in the field of aerospace, if electromagnetic interference affects the navigation and communication systems of aircraft, it will pose a serious threat to flight safety. Effectively suppressing electromagnetic interference has become a key task to ensure the normal operation of electronic equipment and improve its reliability.

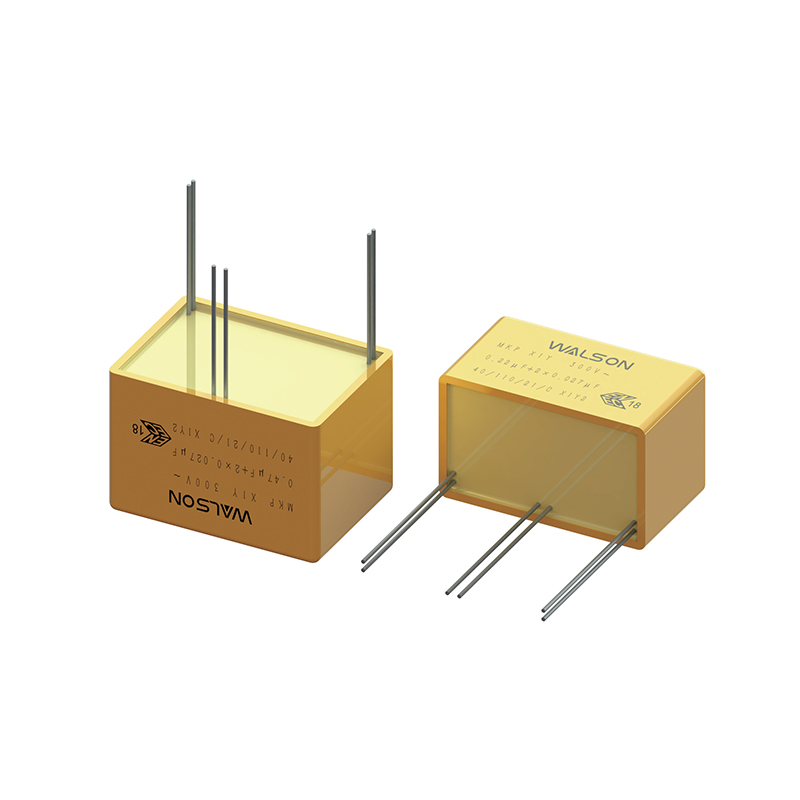

Among many electromagnetic interference suppression methods, Capacitor Module for Electromagnetic Interference Suppression plays an irreplaceable and important role. Among them, Class X and Class Y interference suppression capacitors, as the core components of electromagnetic interference filters, respectively perform "magic" for differential mode interference and common mode interference. Differential mode interference is usually generated by the switching power supply, motor, etc. inside the equipment, and manifests as interference signals between the live wire and the neutral wire; common mode interference originates from the potential difference between the equipment and the earth, or the coupling of the external electromagnetic field, and manifests as interference signals between the live wire, the neutral wire and the ground wire. Class X capacitors are like a brave "differential mode guard", connected between the live wire and the neutral wire, and bypass the differential mode interference signal with its own capacitance characteristics, so that it cannot "break into" the subsequent circuit, thereby ensuring the pure power supply of the circuit; Class Y capacitors are like a "common mode guardian", connected between the live wire and the ground wire, and the neutral wire and the ground wire, respectively, to introduce the common mode interference signal into the earth and eliminate its adverse effects on the circuit. The two work together to build a solid electromagnetic protection barrier for electronic equipment.

The unique mission of Class X1 and Class Y2 capacitors

Class X1 and Class Y2 interference suppression capacitors stand out among many Class X and Class Y capacitors, and shoulder a special and important mission. With its excellent high-voltage resistance, X1 capacitors can work stably in high-voltage environments greater than 2.5kV and less than or equal to 4kV, which makes it easy to deal with high-intensity pulse interference such as lightning strikes and large equipment startup. In the power system, when struck by lightning, extremely high voltage pulses will be generated instantly. X1 capacitors can quickly bypass these high-voltage pulses to protect power equipment from damage and ensure the continuity and stability of power supply. Y2 capacitors are suitable for occasions where there is no risk of electric shock when the capacitor fails. They have excellent performance in suppressing common-mode interference, especially in being able to withstand 5kV pulse voltage shocks without breakdown, providing reliable protection for the safe operation of electronic equipment. In communication equipment, Y2 capacitors can effectively suppress common-mode interference, ensure stable signal transmission, and allow information to flow unimpeded in spaces with complex electromagnetic environments.

In actual application scenarios, X1 and Y2 capacitors can be seen everywhere. In industrial automation control systems, a large number of motors, inverters and other equipment will generate strong electromagnetic interference during operation. X1 capacitors are used to suppress differential mode interference, and Y2 capacitors are used to suppress common mode interference. The two work together to ensure the stable operation of the control system and enable the equipment on the production line to work together accurately and efficiently. In the field of new energy vehicles, there are many on-board electronic devices, and battery management systems, motor drive systems, etc. have extremely high requirements for electromagnetic compatibility. X1 and Y2 capacitors are widely used in these systems to effectively suppress electromagnetic interference, ensure the normal operation of automotive electronic equipment, and improve the safety and reliability of new energy vehicles. In the field of smart home appliances, such as smart refrigerators and smart air conditioners, X1 and Y2 capacitors can reduce the electromagnetic interference generated by home appliances during operation, avoid affecting other surrounding electronic equipment, and also improve the stability and service life of home appliances themselves, bringing users a more convenient and comfortable use experience.

Analysis of the advantages of triangle connection

X1 and Y2 interference suppression capacitors use a triangle connection method. This ingenious connection strategy contains many unique advantages, making it shine in the field of electromagnetic interference suppression. From the perspective of improving electrical performance, delta connection can significantly improve the voltage resistance of capacitors. In delta connection, the voltage borne by each capacitor is the line voltage, and its voltage distribution is more reasonable compared to star connection. Taking a three-phase circuit as an example, the line voltage is 3 times the phase voltage, which means that under the same working voltage requirements, capacitors with delta connection can use products with relatively low voltage resistance, thereby reducing costs and improving system reliability. For example, in some industrial high-voltage equipment, by using delta-connected X1 class capacitors, electromagnetic interference problems in high-voltage environments can be effectively dealt with to ensure the stable operation of equipment.

Delta connection can also enhance the capacitor's ability to suppress harmonics. In modern power systems and electronic equipment, harmonic pollution is becoming increasingly serious, and harmonics can cause equipment heating, reduced efficiency, and shortened life. The capacitor bank connected in a delta can form a low-impedance path to shunt harmonic currents of a specific frequency, thereby reducing the impact of harmonics on the circuit. Studies have shown that for the third harmonic, the capacitor bank connected in a delta can provide about 90% of the harmonic current shunt, effectively improving the power quality. In some occasions with extremely high requirements for power quality, such as data centers and precision manufacturing plants, triangle-connected X1 and Y2 capacitors are widely used for harmonic suppression, creating a good power environment for the stable operation of equipment.

From the perspective of compactness and space utilization, triangle connection has obvious advantages. Compared with other connection methods, triangle connection does not require additional neutral point lead wires, reducing the complexity of wiring and space occupancy. In some electronic devices with extremely strict requirements on space dimensions, such as smartphones and tablets, compact circuit structure is essential. The use of triangle-connected X1 and Y2 capacitors can more efficiently utilize limited space, making the design of the equipment thinner and more compact. At the same time, this connection method also reduces the length and number of connecting wires, reduces line resistance and inductance, and further improves the performance of the circuit. In the field of aerospace, the requirements of equipment on weight and space are almost harsh. The capacitors with triangle connection have become the first choice for electromagnetic interference suppression solutions due to their compact structure and high space utilization, making important contributions to the lightweight and high performance of aerospace equipment.

The exquisiteness of the three-terminal lead-out structure

The integrated structure of the three-terminal lead-out gives the X1 and Y2 class interference suppression capacitors unique performance advantages and application flexibility. This structure plays a significant role in improving the electrical performance of the capacitor. In a high-frequency environment, the traditional two-terminal capacitor will increase the impedance of the capacitor due to the presence of lead inductance, thereby reducing its ability to suppress high-frequency interference signals. The three-terminal lead-out structure effectively reduces the influence of lead inductance through clever design. One of the lead-out terminals is used as a common terminal, and forms a specific electrical connection method with the other two lead-out terminals, so that the capacitor can maintain a low impedance at high frequencies and better play a bypass role for high-frequency interference signals. For example, in high-frequency communication circuits, the signal frequency is usually above the GHz level. The three-terminal lead-out X1 and Y2 class capacitors can effectively suppress high-frequency electromagnetic interference, ensure the pure transmission of signals, and improve the communication quality.

The three-terminal lead-out structure also brings great convenience to the installation and use of capacitors. In the actual assembly process of electronic equipment, the three-terminal lead-out capacitor can be more conveniently connected to the circuit board, reducing the complexity and error probability during the installation process. Its integrated structure makes the capacitor's position on the circuit board more regular, which is conducive to improving the layout density of the circuit board and optimizing the circuit design. In some large-scale electronic products, such as computer motherboards and mobile phone motherboards, three-terminal lead capacitors are widely used because of their convenient installation and regular position, which improves production efficiency and reduces production costs. At the same time, this structure is also convenient for the maintenance and replacement of capacitors. When the capacitor fails, maintenance personnel can operate more quickly and accurately, reducing equipment downtime and improving equipment availability.

In different types of circuits, the three-terminal lead structure shows excellent adaptability. In differential circuits, the three-terminal lead capacitor can effectively suppress differential mode interference and common mode interference through a reasonable connection method, and improve the circuit's anti-interference ability. In the switching power supply circuit, the three-terminal lead structure of the capacitor can better cope with the high-frequency noise and voltage spikes generated during the switching process, and ensure the stable output of the power supply. In the analog signal processing circuit, the three-terminal lead capacitor can flexibly adjust its connection method according to the specific needs of the circuit, realize the precise suppression of interference signals of different frequencies, and improve the quality of the analog signal. Whether in complex industrial control circuits or in precision medical electronic circuits, the X1 and Y2 capacitors with three-terminal lead structures can provide reliable guarantees for the stable operation of the circuits with their excellent adaptability.

Synergistic effect of integrated structure

Designing X1 and Y2 interference suppression capacitors as an integrated structure with triangle connection and three-terminal lead is not a simple combination of forms, but contains profound synergistic effects, which show significant advantages in many aspects. From the perspective of performance synergy, the triangle connection and the three-terminal lead structure cooperate with each other to achieve all-round and efficient suppression of electromagnetic interference. The triangle connection improves the capacitor's withstand voltage and harmonic suppression capabilities, while the three-terminal lead structure reduces the lead inductance and enhances the suppression effect of high-frequency interference signals. The two work together to enable X1 and Y2 capacitors to perform excellent interference suppression performance in complex electromagnetic environments with different frequency bands and different interference types. For example, in power electronic equipment, there are both low-frequency harmonic interference and high-frequency switching noise interference. The integrated structure of X1 and Y2 capacitors can effectively suppress both interferences at the same time to ensure the stable operation of the equipment.

The integrated structure also has a significant synergistic improvement in reliability and stability. This structure reduces the connection points inside and outside the capacitor, reducing the probability of failure due to poor connection. At the same time, the integrated design makes the mechanical structure of the capacitor more stable and can better adapt to harsh working environments such as vibration and impact. In the field of automotive electronics, vehicles are subject to various vibrations and impacts during driving. The integrated structure of X1 and Y2 capacitors can maintain stable performance and provide reliable electromagnetic interference suppression for on-board electronic equipment. In addition, the integrated structure also facilitates the overall quality control and inspection of the capacitor, improves the consistency and reliability of the product, and reduces the cost of after-sales maintenance.

From the perspective of manufacturing and application, the integrated structure brings significant convenience and cost advantages. In the manufacturing process, the integrated structure simplifies the production process, reduces the number of parts and assembly procedures, improves production efficiency, and reduces manufacturing costs. At the same time, since the integrated structure capacitor has better performance consistency, in the mass production of electronic equipment, it can reduce product quality problems caused by capacitor performance differences and improve product yield. In terms of application, the integrated structure X1 and Y2 capacitors are more convenient to install, and the connection of the capacitor can be completed in one installation operation, reducing installation time and labor costs. Its compact structure is also conducive to the miniaturization design of electronic equipment, meeting the needs of modern electronic equipment for lightness, thinness and high performance. In smart home devices, the integrated structure capacitor can not only effectively suppress electromagnetic interference, but also provide support for the miniaturization design of the equipment, making smart home devices more beautiful and practical.

简体中文

简体中文 English

English Español

Español