- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why Are Polypropylene Film Capacitors Preferred Over Other Types of Capacitors?

Why Are Polypropylene Film Capacitors Preferred Over Other Types of Capacitors?

Introduction: Understanding Polypropylene Film Capacitors

Capacitors are essential components in electronic circuits, used for energy storage and smoothing signals. Among the various types of capacitors, polypropylene film capacitors have gained significant popularity in both consumer and industrial applications. Known for their reliability and performance, these capacitors offer distinct advantages over other types, such as ceramic, electrolytic, and tantalum capacitors.

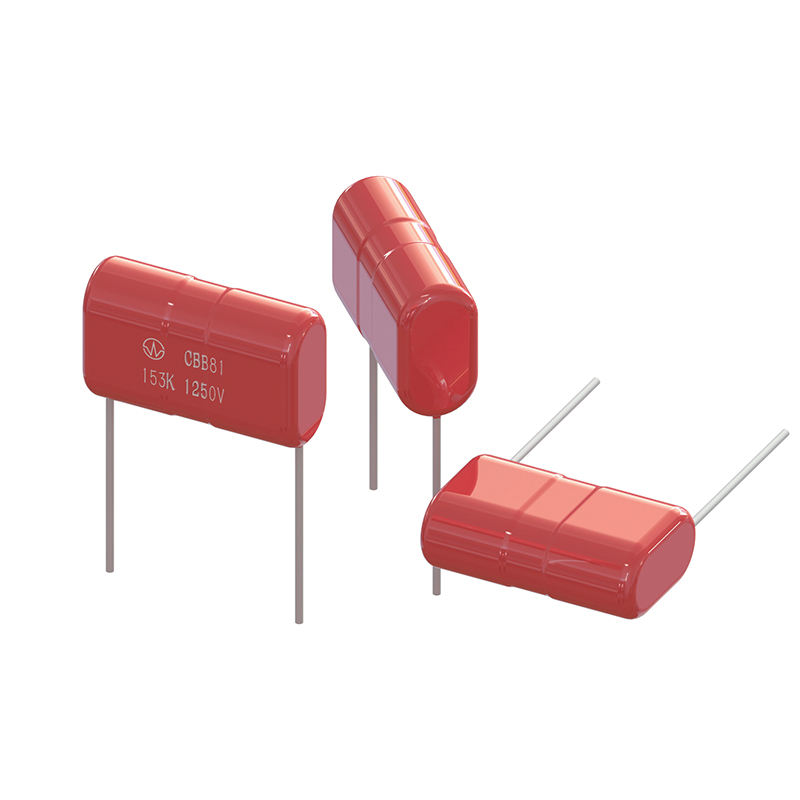

What Is a Polypropylene Film Capacitor?

A polypropylene film capacitor is a type of capacitor that uses a polypropylene plastic film as its dielectric material. These capacitors are primarily valued for their high insulation resistance and thermal stability. Polypropylene is a non-polar, highly stable dielectric material, which makes it an ideal choice for applications requiring reliable performance under a variety of operating conditions.

Polypropylene film capacitors come in a variety of sizes and voltage ratings. They are typically used in high-frequency applications and environments that require precise capacitance values. These capacitors are also known for their durability and ability to withstand electrical stress, making them suitable for both low and high voltage applications.

Key Advantages of Polypropylene Film Capacitors

High Stability and Reliability

Polypropylene film capacitors are renowned for their long-term stability and resistance to electrical and environmental stress. The dielectric material used in these capacitors allows them to maintain a consistent capacitance value over time, even under fluctuating temperature and humidity conditions.

Low Loss and Low ESR

One of the significant benefits of polypropylene film capacitors is their low equivalent series resistance (ESR). This characteristic helps minimize energy losses in circuits, ensuring that the capacitor can operate efficiently in power-sensitive applications. Additionally, these capacitors exhibit low dissipation factors, which is crucial for high-frequency filtering applications.

High Voltage Capability

Polypropylene film capacitors can handle higher voltages compared to many other capacitor types, making them a preferred choice for high-voltage applications. This capability is particularly important in power electronics, automotive systems, and telecommunications equipment, where higher voltage levels are common.

Excellent Temperature and Thermal Stability

These capacitors can function effectively across a wide temperature range, from -40°C to 85°C or even higher, depending on the capacitor’s specific design. This thermal stability allows them to be used in environments where other capacitor types might fail, such as in outdoor equipment or high-power electronics.

Long Lifespan

Polypropylene film capacitors are well-known for their longevity. They are not susceptible to electrolyte leakage or dry-out, which is a common issue with electrolytic capacitors. This makes polypropylene capacitors more durable and less likely to fail over time, ensuring a longer service life for electronic devices.

Comparison with Other Capacitor Types

Polypropylene Film vs. Ceramic Capacitors

Ceramic capacitors are commonly used for their small size, low cost, and high capacitance-to-volume ratio. However, they tend to have higher temperature and voltage coefficients, which cause changes in capacitance with variations in temperature and voltage. In contrast, polypropylene film capacitors offer greater stability and less variation under operating conditions, making them ideal for precision applications.

Polypropylene Film vs. Electrolytic Capacitors

Electrolytic capacitors are widely used for energy storage and filtering applications. However, they have a shorter lifespan and are prone to failure due to issues such as electrolyte leakage. Polypropylene film capacitors, on the other hand, offer reliability and do not suffer from these issues, making them more suitable for long-term, high-reliability applications.

Polypropylene Film vs. Tantalum Capacitors

Tantalum capacitors are known for their small size and stable capacitance values. However, they are more expensive and can be more susceptible to failure under surge conditions. Polypropylene film capacitors are a cost-effective alternative that provides similar performance in many applications without the risk of catastrophic failure.

Applications of Polypropylene Film Capacitors

Polypropylene film capacitors are used in a wide variety of applications due to their versatility, reliability, and performance characteristics. Some of the common applications include:

- Power Supply Filters: Polypropylene film capacitors are commonly used in power supply systems for filtering and smoothing DC output, ensuring stable operation of electronic devices.

- Motor Drives: These capacitors are used in motor control circuits to filter high-frequency noise and ensure efficient operation.

- Signal Processing: In signal processing systems, polypropylene film capacitors provide precise filtering capabilities, helping to eliminate unwanted noise from high-frequency signals.

- Automotive Electronics: These capacitors are used in automotive systems to manage voltage regulation, power distribution, and to stabilize circuits in harsh environments.

- Telecommunications Equipment: Polypropylene film capacitors play a crucial role in the performance of communication systems, particularly in high-frequency applications.

Polypropylene Film Capacitor vs. Other Types: A Performance Table

| Feature | Polypropylene Film Capacitor | Ceramic Capacitor | Electrolytic Capacitor | Tantalum Capacitor |

|---|---|---|---|---|

| Capacitance Range | 1nF to 100µF | 1nF to 10µF | 1µF to 1000µF | 1µF to 1000µF |

| Voltage Rating | Up to 400V | Up to 500V | Up to 500V | Up to 50V |

| Temperature Range | -40°C to 85°C or higher | -25°C to 85°C | -40°C to 85°C | -55°C to 85°C |

| ESR (Equivalent Series Resistance) | Low | Higher | Higher | Higher |

| Reliability | High | Moderate | Low | Moderate |

| Cost | Moderate | Low | Low to Moderate | High |

Why Are Polypropylene Film Capacitors Preferred?

Cost-Effective for High-Quality Applications

While polypropylene film capacitors may be more expensive than ceramic capacitors, their performance in high-voltage, high-temperature, and high-reliability environments justifies the additional cost. For applications where failure is not an option, the added investment in polypropylene film capacitors is often considered worthwhile.

Lower Failure Rates

The absence of liquid electrolytes in polypropylene capacitors means that they are far less likely to fail due to leakage or dry-out. This makes them particularly valuable in critical applications where component failure can result in significant damage or downtime.

Improved Efficiency in High-Performance Circuits

Polypropylene film capacitors provide energy efficiency in circuits, reducing losses and enhancing the performance of the system. Their low ESR ensures minimal power dissipation, which is particularly important in high-frequency and power-sensitive applications.

FAQ

1. What are the key advantages of polypropylene film capacitors?

Polypropylene film capacitors offer high stability, low loss, and high voltage capability. They also exhibit thermal stability and a long lifespan, making them ideal for demanding applications.

2. Can polypropylene film capacitors be used in high-frequency circuits?

Yes, polypropylene film capacitors are well-suited for high-frequency circuits due to their low ESR and low loss characteristics, ensuring efficient operation in such applications.

3. How do polypropylene film capacitors compare to electrolytic capacitors?

Polypropylene film capacitors offer better reliability and longevity compared to electrolytic capacitors, which are prone to leakage and dry-out over time. They are ideal for high-reliability applications.

4. Are polypropylene film capacitors more expensive than other capacitors?

While polypropylene film capacitors tend to be more expensive than ceramic and electrolytic capacitors, their performance and reliability make them a cost-effective choice for critical applications.

5. What are some common uses for polypropylene film capacitors?

Polypropylene film capacitors are commonly used in power supply filters, motor drives, signal processing, automotive electronics, and telecommunications equipment due to their reliability and versatility.

Conclusion

As technology continues to advance, the demand for reliable and high-performance capacitors like the polypropylene film capacitor will only grow. Their combination of stability, efficiency, and longevity makes them the preferred choice for a wide range of applications. Whether in consumer electronics, automotive systems, or industrial equipment, polypropylene film capacitors provide the reliability that engineers and designers trust.

简体中文

简体中文 English

English Español

Español