- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

-

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

Web Menu

- Home

- Products

- Applications

- Capacitors for Household Appliances

- Capacitors for Power Supply

- Capacitors for LED Lighting

- Capacitors for Mobile And DSL Appliances

- Capacitors for Automotive& Vehicles

- Capacitors for Photovoltaic Inverters

- Capacitors for Wind Power Plants

- Capacitors for Renewable Energy Systems

- Capacitors for Induction Heating

- Capacitors for Medical Equipments

- Capacitors for Industrial Control

- Capacitors for Power Electric

- Capacitors for Rail Transit

- Capacitors for Smart Grid

- Capacitors for University & Research Instituite (High Energy Physics)

- About Us

- News

- Contact Us

Product Search

Exit Menu

Why the self-healing property of mkp film capacitor is reshaping global applications?

Why the self-healing property of mkp film capacitor is reshaping global applications?

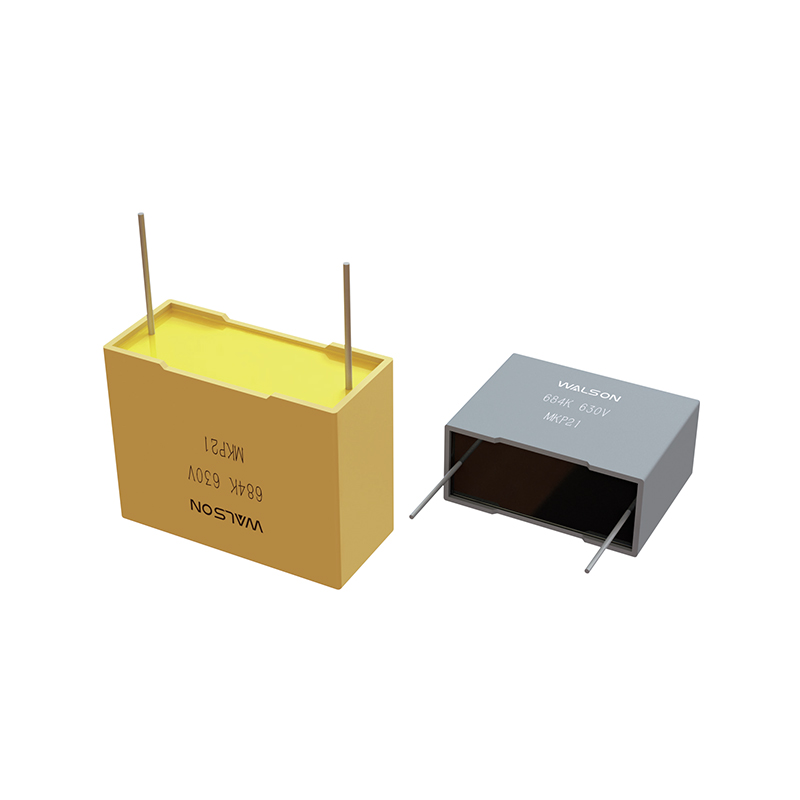

In the landscape of modern electronic components, the MKP film capacitor (Metallized Polypropylene Capacitor) has become a pivotal choice across industries. Known for its combination of high voltage endurance, low ESR, and long operational lifespan, one feature sets it apart from conventional designs: its self-healing property. This single characteristic not only enhances reliability but also redefines how engineers and manufacturers evaluate passive components for power electronics, renewable energy, and industrial applications.

Understanding Self-Healing in MKP Film Capacitor

The self-healing mechanism in an MKP film capacitor refers to the ability of the metallized polypropylene dielectric to recover after a localized breakdown. When an electrical overstress occurs, the thin metallized layer vaporizes around the fault point, isolating the defect and restoring the capacitor’s insulating integrity. This process ensures that the component continues to function effectively without catastrophic failure.

This property directly addresses the critical concerns in applications requiring high voltage capacitors, DC link capacitors, and inverter capacitors: operational safety and system stability. By preventing sudden breakdowns, self-healing extends the capacitor’s usable lifespan and maintains high stability even in challenging environments.

Impact on Reliability and System Design

In high-frequency power conversion systems, low ESR capacitors are essential for minimizing energy loss and heat generation. The integration of a self-healing mechanism within the MKP film capacitor enhances this efficiency further by ensuring consistent dielectric performance over time. Unlike components that degrade irreversibly after electrical stress, MKP capacitors offer predictability and resilience.

This reliability factor plays a crucial role in system design. Engineers can reduce redundancy, simplify maintenance schedules, and optimize space usage, knowing that the capacitor is less prone to failure. Consequently, self-healing contributes to both technical and economic advantages in the deployment of industrial capacitors and renewable energy capacitors.

Market Relevance in Global Electronics

As demand for energy-efficient solutions grows worldwide, MKP film capacitors have gained strong traction in power electronics capacitors and motor drive capacitors. Markets in Europe, North America, and Asia-Pacific have highlighted the self-healing property as a decisive factor in procurement, particularly for applications in renewable energy, electric mobility, and high-performance industrial equipment.

Self-healing does not merely add durability; it enables systems to achieve long lifespan capacitors performance standards. For global markets that prioritize cost of ownership and sustainability, this feature is increasingly aligned with regulatory and environmental expectations.

User Concerns and Market Insights

International users of MKP film capacitors often evaluate products not only on technical merits but also on criteria such as availability, performance under stress, and long-term operational security. Based on industry feedback, the following table summarizes the frequently discussed factors among overseas markets:

| User Concern | Relevance to MKP Film Capacitor | Industry Expectation |

|---|---|---|

| Reliability under High Voltage | Ensured by self-healing property and high insulation strength | Stable operation in demanding power electronics |

| Efficiency at High Frequency | Supported by low ESR design | Reduced energy loss and heat generation |

| Long-Term Stability | Enabled by polypropylene dielectric | Lifespan extending beyond standard capacitors |

| Safety in Operation | Prevents sudden failure due to self-healing mechanism | Lower maintenance and higher confidence |

| Market Availability | Widely produced in various capacitance and voltage ranges | Accessible for global integration in diverse applications |

This overview reflects that the self-healing MKP film capacitor is not simply a passive component but a risk-reducing element within critical systems.

Future Outlook

The emphasis on electrification and renewable integration is expected to keep MKP film capacitors at the forefront of component selection. With their combination of high stability capacitors and safety mechanisms, they are positioned to address evolving challenges in grid-level energy storage, next-generation inverters, and high-efficiency drives.

The self-healing property will remain a key differentiator, especially as global industries demand components that align with sustainability, reliability, and efficiency targets. Engineers and procurement specialists will continue to favor MKP designs that ensure operational security without compromising system compactness or performance.

The MKP film capacitor stands out in the global component market due to its self-healing property, which ensures reliability, stability, and safety across high-demand applications. As industries move toward energy transition and smarter electronic infrastructures, this feature underscores why MKP capacitors are increasingly regarded as the backbone of high-performance and long-lifespan systems.

简体中文

简体中文 English

English Español

Español